Description

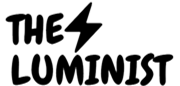

Take your electronics production to the next level with the Place Station Desktop Pick and Place Machine (PNP Machine) a revolutionary, open-source, high-performance desktop solution tailored for Indias growing electronics manufacturing ecosystem. Whether you’re building prototypes, executing batch production, or offering contract manufacturing services, this precision-engineered machine is your key to efficient, professional-grade PCB population without the need for bulky industrial infrastructure.

Built for low-to-mid scale production, the Place Station brings you all the power of a professional SMT assembly line in a compact desktop form. Featuring dual independent nozzles, the machine supports automatic nozzle switching, drastically reducing setup time and improving throughput. From 0402-sized passive components to 30mm ICs, this machine handles a wide range of components ideal for IoT devices, LED boards, wearables, consumer electronics, and automotive modules.

Place StationDesktop Pick and Place

The Place station brings accurate, affordable, and speedy population to your benchtop.

Orders of magnitude cheaper than its next competitor, the Place station leverages the linear motion control advancements of the past decade from the commoditization of desktop FDM 3D printers andapplies them to the SMT industry. Removing the need for high-pressure air or industrial power hookups

means the Place station can easily be deployed on your production line, or in the office

Making Machines for Mid-Scale Manufacturing

Board Size

Board Size

The two staging plates provide a usable work area of 400mm in the X axis, and 240mm in the Y, with camera, datum board, and nozzle rack to be considered. While avoiding these, boards 120mm X 400mm, or 240mm x 270mm With a third staging plate, these expand to 240mm x 400mm, or 360mm x 270mm

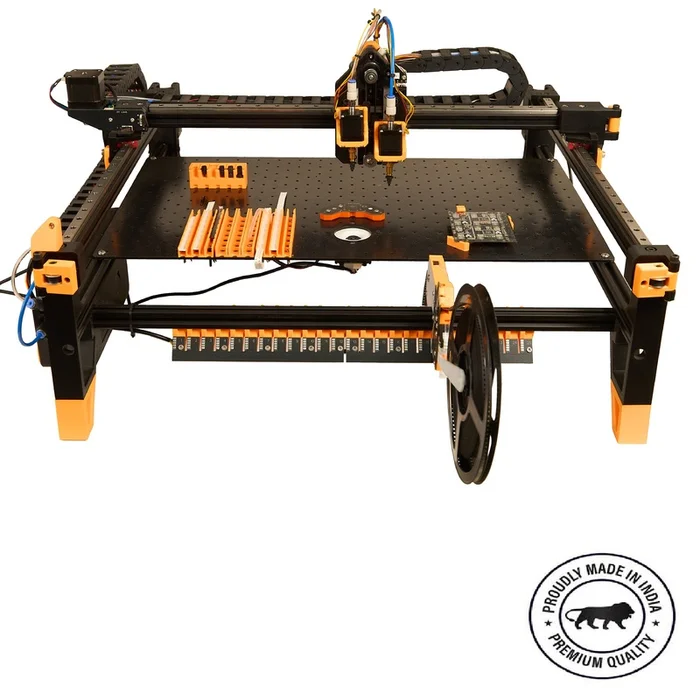

Dual Nozzles

Dual Nozzles

With two nozzles, the Place station is capable of picking a wide variety of parts without needing to perform a nozzle tip swap (which the machine is capable of doing fully automatically). Correctly choosing your tips allows for the machine to pick 0402s and TQFP- 100s without a swap, greatly increasing job speed.

Control Software

The Place station is controlled using OpenPnP, the industrystandard for pick and place machines of this scale.The

machine comes with ready-made con guration les, and we walk you through every step of setup and calibration in our thorough documentation. OpenPnP runs crossplatform, so you’re ready to run jobs with whatevercontrol computer you have available.

Supported Components

– Down to 0402 Passives

– Up to 30mm x 30mm

– Up to 25 gram weight

– Up to 20mm tall

– BGA Pitch – 0.8mm

– IC Pitch – 0.4mm

Making Machines for MidScale Manufacturing

![]()

![]()

![]() Vacuum Detection

Vacuum Detection

Two 24 bit pressure sensors comeinstalled on each nozzle air line,allowing the machine to immediately detect a part mis-pick. This savestime by removing the need to jog tothe bottom camera for part detectionif a mis-pick occurs.

High Speed

Equipped with high-quality linear rails,the Place station is incredibly fast formachines in its class. It has TMC2209stepper drivers for each axis, meaning the machine’s motor movements arealmost perfectly quiet, while providingexceptional current delivery

Configurable

The Place station is highly configurable due to its staging plate system. Thestaging plates are easily added orremoved depending on your needs, and the standard Peek Array mounting hole grid allows for maximum exibilityin mounting placement.

Easy Setup

Getting your Place station assembledand operational takes less than anhour. Every machine comes with adedicated calibration kit, which walksyou through setup and calibration ofthe machine so you’re ready to runyour own jobs.

Open Source

Everything about the Place station iscompletely open source. From themechanical CAD, to the circuit boarddesign, to the software, everythingabout the machine is fully availableand ready to download.

Docs and Support

Our fully-documented assembly andcalibration process is available online,

and there is always someone to help.

Vision System

Top Camera

Top Camera

The Place station comes with an integrated HD camera mounted on the head. This camera is instrumental in a number of calibration procedures that allow the machine to placeparts at a high speed, with high precision. The top camera helps navigate the machine’sworking area, automatically nds feeder pick locations, and performs ducial calibrationon the PCB being populated to optically calibrate every job.

Bottom Camera

The Place station also comes with a stationary camera mounted to the rst staging plate on the machine. This camera provides rotational and translational offset calibration forthe parts after they’ve been picked by the nozzle. After picking, the machine can optionallymove the picked part over the bottom camera and perform vision calibration to ensurethat the part is placed exactly where it needs to go

Making Machines for Mid-Scale Manufacturing

Feeders

8mm and 12mm feeders are available now. 16mm feedersare in development along with 24mm feeders. 8mm and12mm take up one feeder slot, allowing up to 50 to bemounted to the machine at a time. 16mm and 24mmfeeders take up two slots. Feeders use an open source protocolcalled Photon, whichallows for feeders to self-report complex data back to thecontroller, including feeder position, feed and tape status,along with the feeder’s universal ID. Because of this rich communication, feeders can be swapped to different slots and the Place station is ableto dyamically nd, command, and pick from the newly placed feeder. This means job setup and feederconfiguration is order of magnitudes easier than with other systems.

If you have components in tape widths not compatible with powered feeders, or you’ve fully lled yourslots and have remaining parts in your job, the Place station is con gured to support a wide array of stripfeeders, with widths ranging from 8mm, 12mm, 16mm, 24mm, 32mm, and 44mm tape.

Staging Plate Count

The basis for the majority of your machine’s configis the number of staging plates that you havemounted to the frame. Using only the default two plates means you have both the front and back railavailable for powered feeders, allowing you to fit to up to 50 total. This is the recommended configuration. If you’re populating very large boards that require the third plate for mounting, then only the front rail is available for powered feeders. You might alsoneed three staging plates if you have many tape widths not supported bypowered feeders.

Config Tool

It’s easy to nd the optimal configuration for yourPlace station using our Config Tool. Simply input the unique part count for each tape with in your job, assign which parts are priority to be fullyautomated with a powered feeder, and an optimal Place station configuration will be rendered in full 3D.We also outline all the parts required for yourconfig, and a link to purchase them.

Summary:-

– Up to 79 unique components

– Supports down to 0402

– Prototype Runs

– Contract Work

– Makerspaces, Universities

Phone: +91 7738961235

Applications:

-

Low-to-mid volume PCB production

-

Rapid prototyping for startups and design houses

-

Contract assembly work for Indian SMEs

-

Engineering colleges, research labs, and makerspaces

-

Batch production for IoT, automotive, LED, and consumer electronics

Data Sheet :- Click Here

Key Features:

-

Dual Nozzle System: Supports wide range of SMD components without frequent nozzle changes

-

Top & Bottom Cameras: High-precision alignment and mis-pick detection

-

OpenPnP Control Software: Cross-platform, open-source, fully configurable

-

Silent Stepper Drivers: Ultra-quiet operation with TMC2209 drivers

-

Vacuum Detection: 24-bit pressure sensors detect part pickups in real-time

-

Fully Open Source: Mechanical CAD, electronics, and software all customizable

-

Flexible Staging Plates: Supports large boards and optimized feeder configurations

-

Made in India, No air compressors or 3-phase required

Technical Specifications:-

Package Includes:

-

1 Place Station Pick & Place Machine

-

2 HD Cameras (top & bottom vision)

-

1 Calibration Kit

-

1 OpenPnP Configuration & Support Guide

-

1 Power Cable (India-compatible)

-

1 User Manual (Digital)

-

(Optional) Strip & Powered Feeders as per order

Reviews

There are no reviews yet.